Facilities

Chambers:

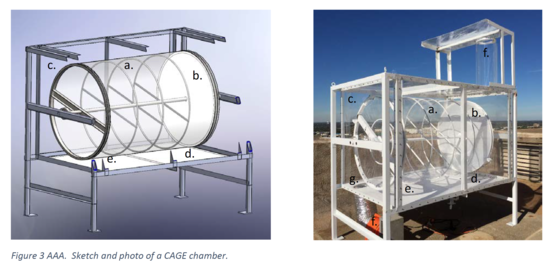

Captive Aerosol Growth and Evolution (CAGE) Chamber:

This environmental chamber is unique because it can be operated in the field as opposed to being confined to the indoors. The chamber is designed to rotate along the horizontal axis to minimize loss of particles to the walls. Light transmitting Teflon chamber walls and acrylic enclosure walls will be used to mimic ambient UV/VIS conditions. The temperatures inside of the chambers will be controlled to match ambient temperatures. The CAGE chamber holds the potential to obtain new results on small particle growth and aging and has the adaptability to study various systems and parameters.

UCR Oxidation Flow Reactor (UCR-OFR):

Oxidation flow reactors (OFRs) have developed very rapidly over the past few years and are now used by many groups around the world. Inside the UCR-OFR, a very high hydroxyl radical concentration is maintained, such that sampled air experiences the equivalent of several hours or days of oxidative chemistry in just a few minutes residence time, during which interaction with the walls is limited. The UCR-OFR uses a diffuser at the inlet of the reactor to help expand the flow to the diameter of the reaction section while maintaining an idealized laminar flow profile. Temperature gradients within the reaction section are limited to reduce convective mixing. A UV lamp (254 nm) is used to generate OH radicals inside of the reactor. The UCR-OFR will be used to analyze VOC oxidation and secondary aerosol formation.

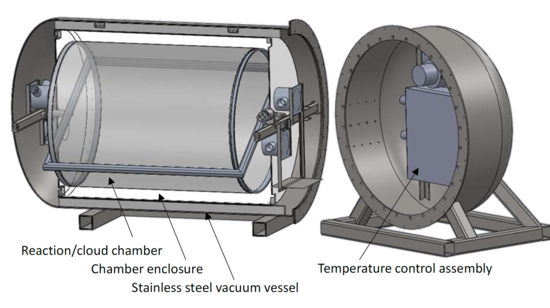

Multiphase Aging and Production of Particles (MAPP) Chamber:

Our research group has recently developed the MAPP chamber to study cloud processing of aerosols. The cylindrical chamber has a volume of about 1 m3 and is contained by a stainless steel vessel. It realistically simulates cloud formation utilizing adiabatic expansion. Its double-wall design allows for independent vacuum control of the reaction chamber and the surrounding enclosure. The reaction chamber is constructed from Teflon in order to be inert and transparent. To have a low heat capacity and a high light reflectivity, the chamber enclosure has multiple layers. Two xenon-arc lamps outside of the reaction chamber are used to drive photochemical reactions. Similar to the approach commonly used to retain large bioparticles, the reaction chamber rotates at a constant rate. Seed particles will be injected into the chamber to provide cloud condensation nuclei on which to observe aqSOA growth.

Instrumentation:

Instruments |

|---|

| Gas Phase Measurements |

| Gas Chromatography Flame Ionization Detector (GC-FID) |

| Trace Level Chemiluminescence Photolytic NOx Analyzer |

| UV Absorption O3 Analyzer |

| Trace Level UV Fluorescence SO2 Analyzer |

| Particle Phase Measurements |

| Cloud Condensation Nuclei Counter CCNc |

| Scanning Mobility Particle Sizer (SMPS) |

| Aerodynamic Particle Sizer (APS) |

| Differential Mobility Analyzer |

| Tandem Differential Mobility Analyzer |